Industrial Explosion Protection ATEX Technologies Overview

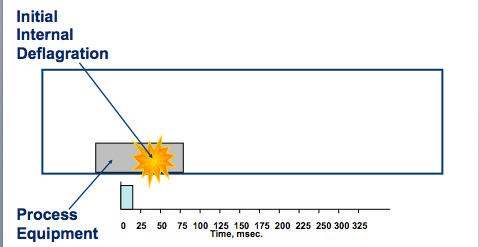

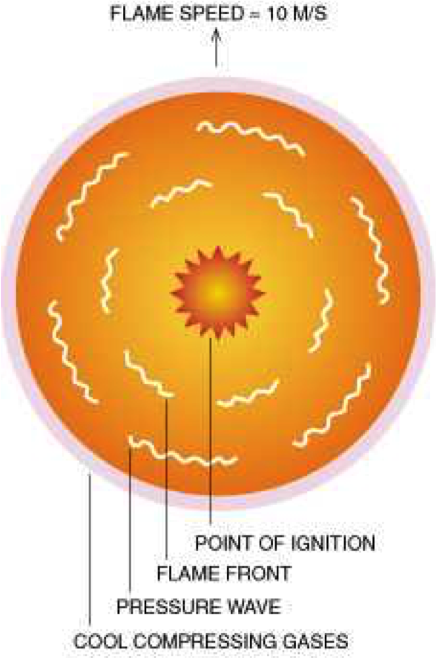

Commonly begins with the ignition of a fuel that burns very rapidly.

Produces a large and sudden release of gas

An explosion need not involve a fire.

When a container bursts from increased internal pressure, sudden release also called an explosion.

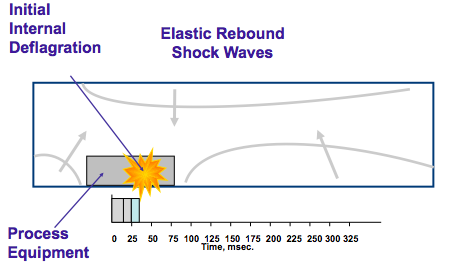

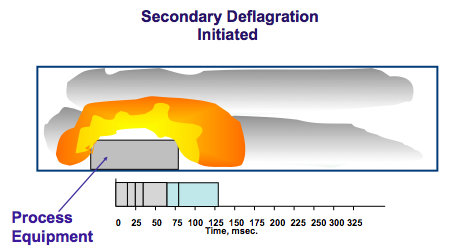

Secondary dust explosions, due to inadequate housekeeping and excessive dust accumulations.

Secondary dust explosions due to propagation through interconnected ducts, chutes, conveyors, …etc.

SECONDARY EXPLOSIONS ARE THE MAIN THREAT TO PERSONNEL AND PROPERTY!

Flame Speed 30 ft/s

30 ft/s (9m/s)

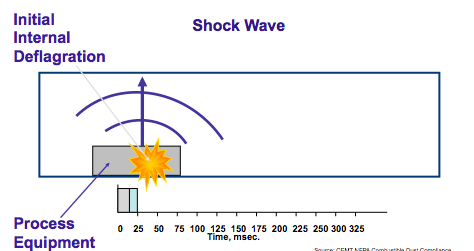

Pressure Wave 1100 ft/s

1100 ft/s (335 m/s)

Chemical

Petrochemical

Grain

Food

Pharmaceutical

Aerosol

Steel

Cement

Wood

•Ingredion (National Starch)

•Firmenich

•Givaudan Roure

Food Additives

•Solae Company

•International Flavors and Fragrances

Sugar •Western Sugar•American Sugars•Imperial Sugars•American Crystal Sugars,Dairy Products (powder) •Kraft Foods•AC Humco•Nestles

Dust Collectors Reactors

Bins, Hoppers, Silos

Pneumatic Conveying

Mechanical Conveying

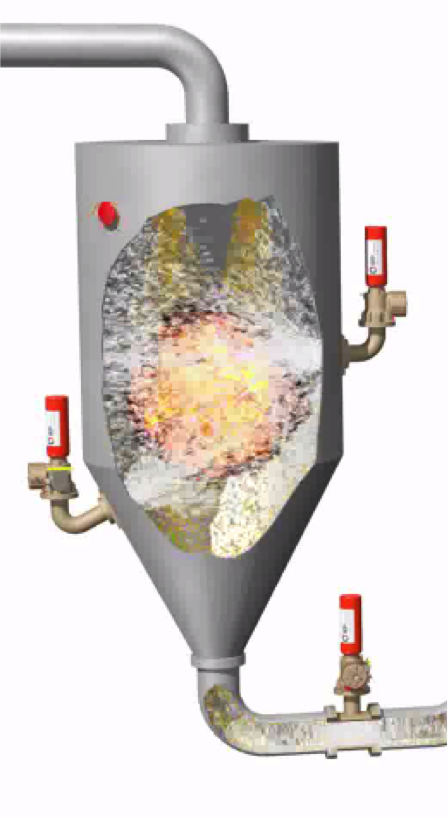

Cyclones

Dryers (Spray, Fluid Bed, Rotary)

Mixers, Blenders

Mills, Grinders, Pulverizers

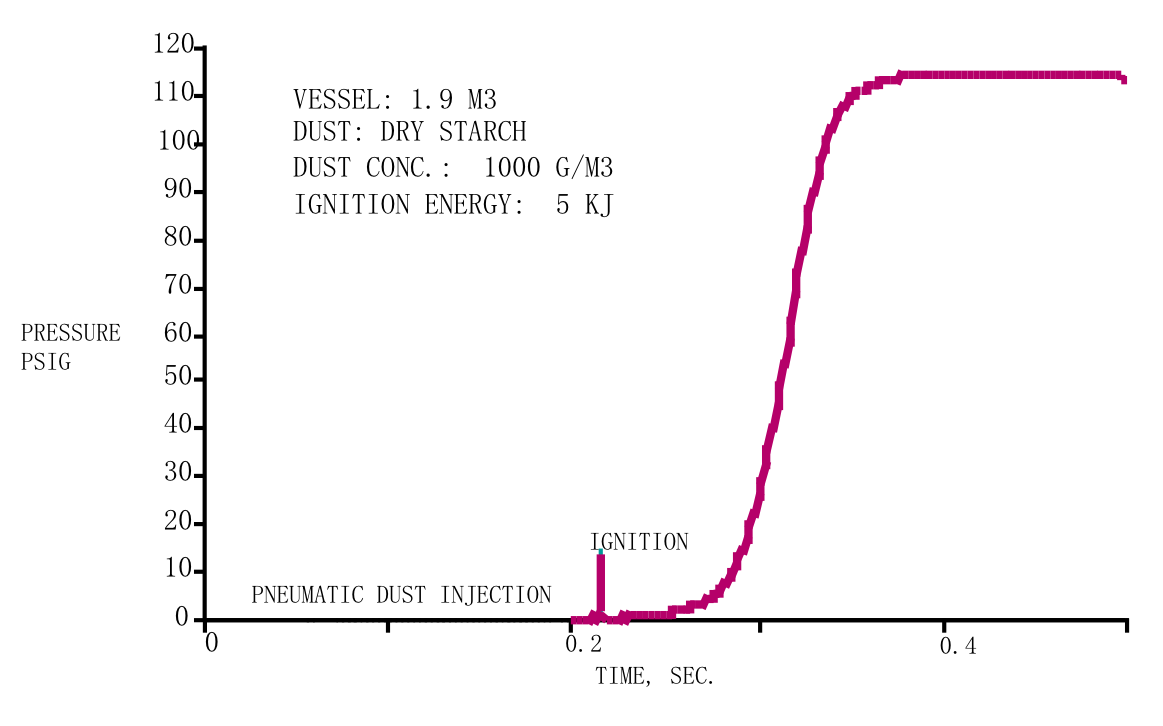

Deflagration Pressure vs. Time

ST Classification:ST-1, ST-2, ST-3; Rst Value:1-200;201-300,301-above

Example:Pittsburgh

seam

coal has a Kst

of 129 bar-m/sec,making

it an ST-1 dust Applicable

Codes (USA)