Home / Sand Blasting

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Tel

- *Title

- *Content

Company

Categories

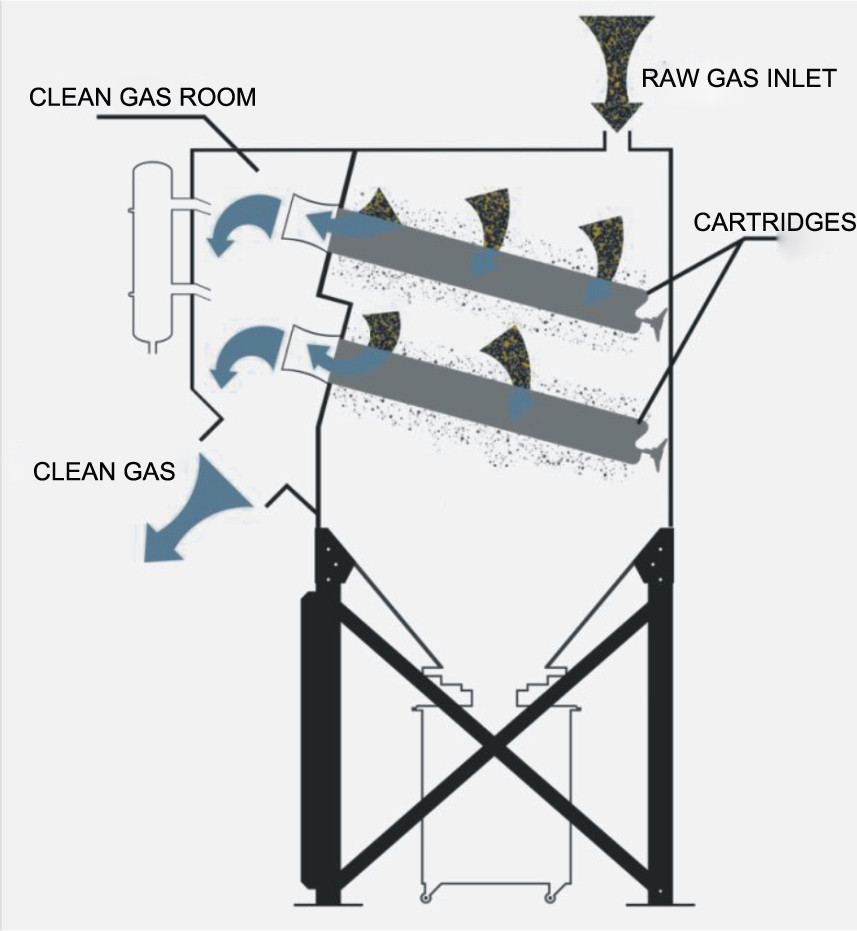

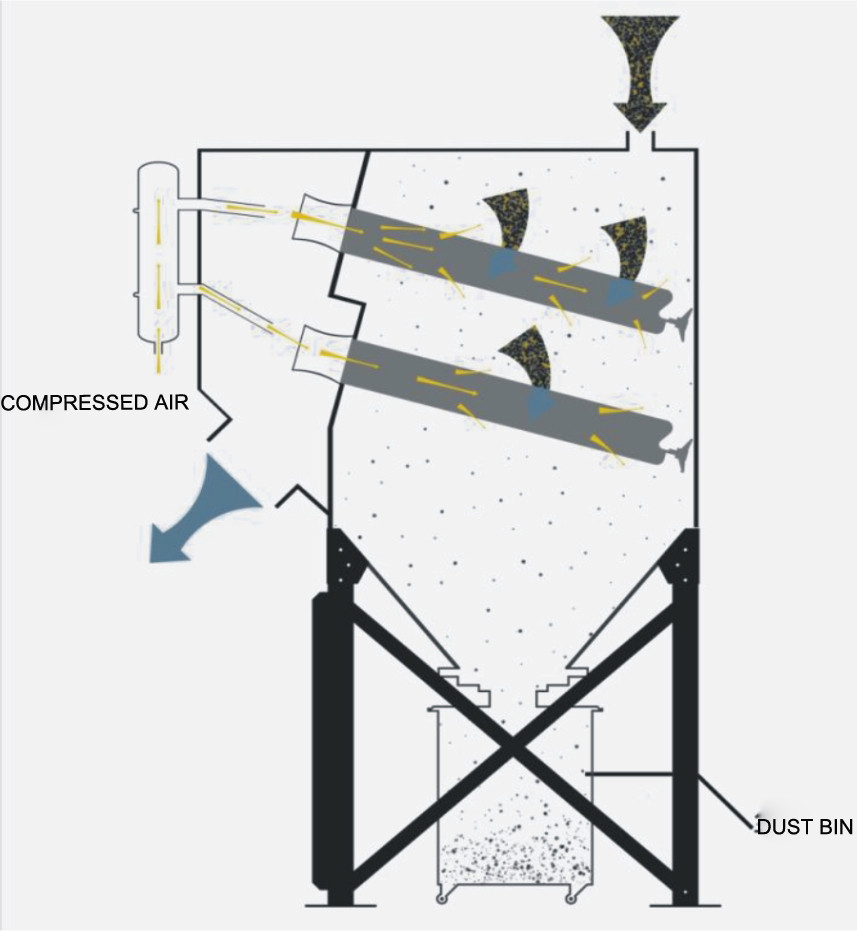

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

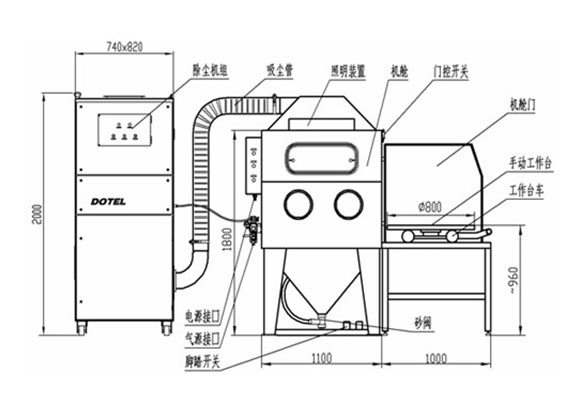

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web