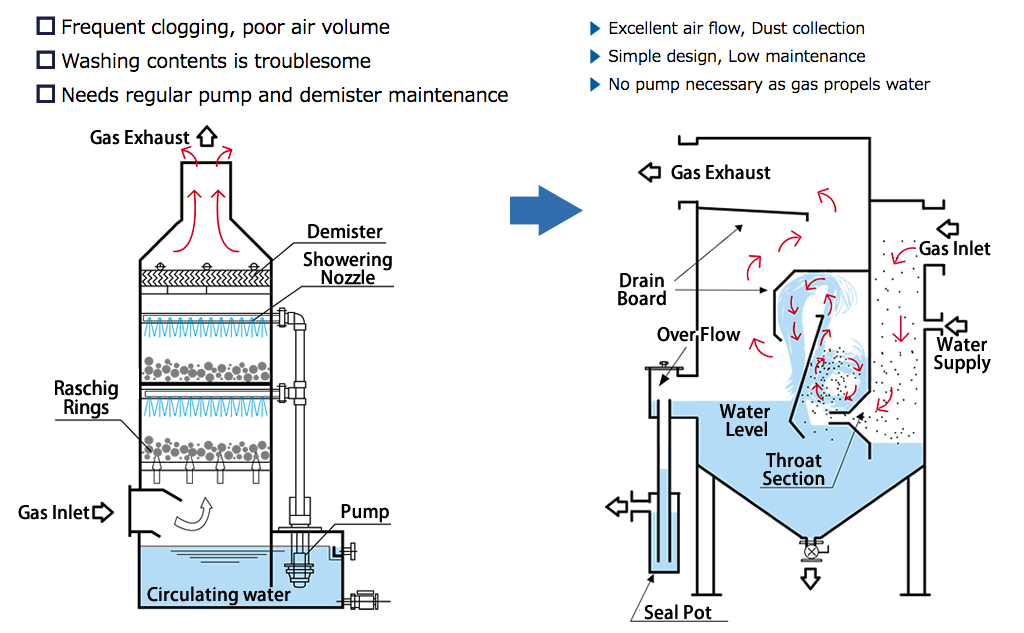

• Features:

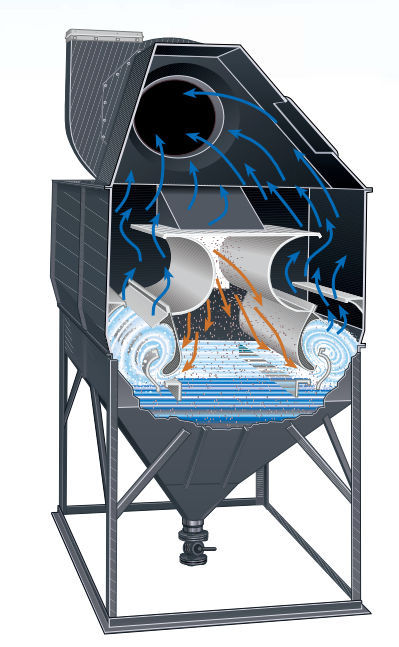

1:High dust removing efficiency through hydraulic force

2:Automatic water feeding device, easy in maintenance

3:Good dust removing effect for sticky and hydrophilic dust particles

4:Low running resistance, low power consumption

• Operation principle:

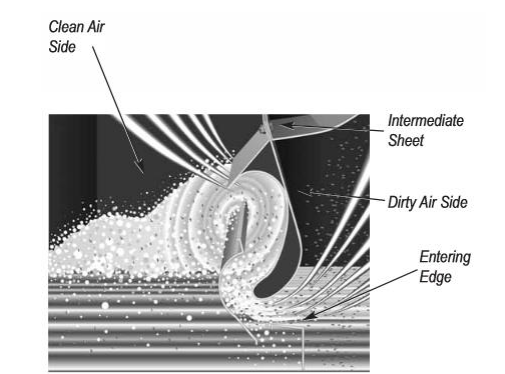

During operation, dust air passes through arc-shaped slot with high flow speed after it enters the purifying tank. Air stream in the slot turns sharply and blends forcefully with water, forming a water curtain at the slot exit that facilitates full contact between dust and water and enables dust to dissolve into water. Purified air is discharged out from water-retaining plate after moisture removed. By recycling water in the tank, Water consumption is therefore minimal, except for loss from evaporation. Water lost is replenished by automatic water refilling device to maintain water level. Sludge on the dust remover shall be cleaned regularly.

• Applicable:

It is highly effective in treating sticky, high temperature, toxic and harmful gases. It's widely used in pharmaceutical, metallurgy, chemical and power industries.Wet scrubber for flammable dust(metal grinding, polishing, buffing,brazing)

water scrubbers for Thermal exhaust gas/hot steam vapor/hot gas dust scrubber for hygroscopic dust(sugar rotary dryer,thermal-spray application Watery dust remover for poisonous gas absorption, acid and alkali neutralization air scrubber for pharmaceutical sensitization powder: penicillin,Pill Encapsulation

gas scrubber for odor absorption(VOCS treatments)