• Features:

1:Submicron cylinder filtering, easy for replacement

2:Easy in operation and maintenance

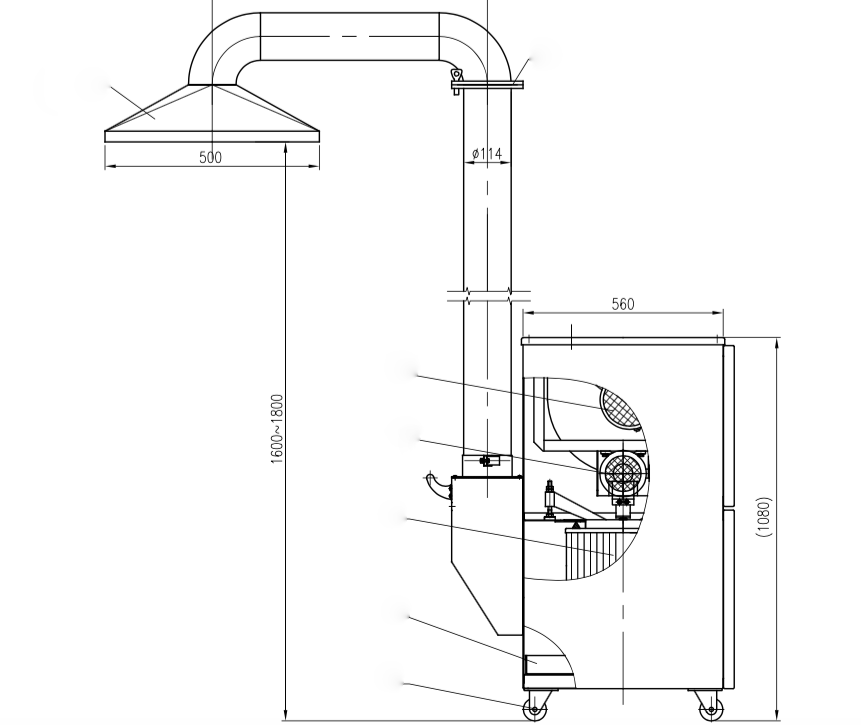

3:Designed on load-and-go basis

4:Automatic off-line dust removing

5:Multiple to be connection locations for air inlets and outlets

6:Easy for transportation

• Operating:

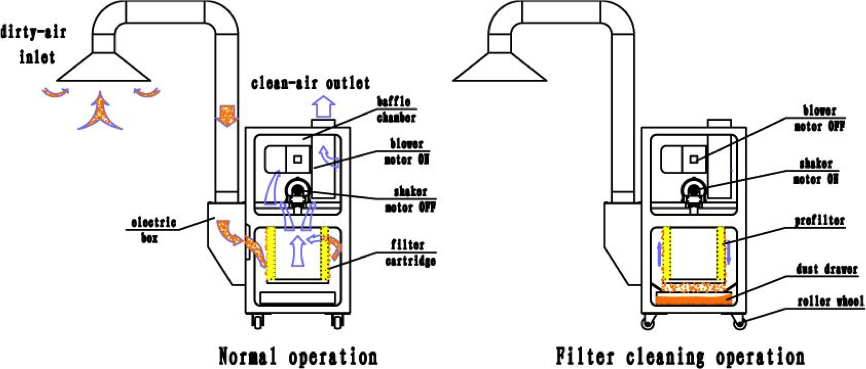

Normal operation: switch on the power, turn on the fan, dust air enters the cylinder from dust source through suspended hood, air hose and air inlet. Flow rate drops suddenly due to air stream soaring; big grain dust separates from dust air and than sink into dust storage tan k, other small grain dust remains at the outer well of filter element under the influence of filtering, colliding, hooking and static electricity. Purified air is discharged from the fan to air outlet via the anechoic chamber above. Dust cleaning operation: dust cleaning goes on discontinuously; high-frequency vibration will enable the filter to regenerate after the fan shuts down.

• Applicable fields:

Application environment: temperature: -10-55 centigrade, relative air humidity no higher than 85%, without compressed air source; Application industry: chemistry industry, pharmaceutical industry, food processing, metal processing, compound material, electronics, building materials, electrostatic coating and other fine air particles.