• Features:

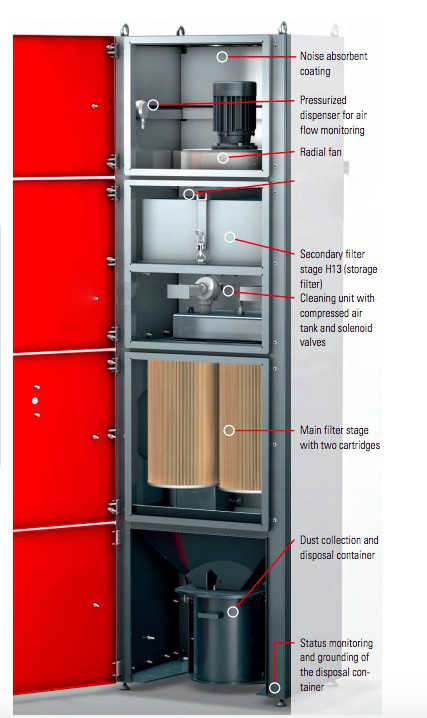

1:Submicron cylinder filtering, easy for replacement

2:Automatic online pulse dust removing

3:Easy in operation and maintenance

4:Multiple tube connection locations for air inlets and outlets

5:Designed on load-and-go basis

6:Larger filtering area

7:Filter cylinder being more pressure-resistant and having longer service life

• Operation principle:

Normal operation: switch on the power, turn on the fan, dust air enters the air box from dust source through suspended hood, air hose and air inlet. Flow rate drops suddenly due to air stream soaring; big grain dust separates from dust air and then sink into dust storage tank, Other small grain dust remains at the outer well of filter under the influence of filtering, colliding, hooking and static electricity. Purified air is discharged from the fan to air outlet via the anechoic chamber above. Dust cleaning operation: online dust removing is adopted, no machine shutdown is needed; pulse valve is controlled by controller, back-blowing is conducted on the filter drum periodically, time is set according to actual dust density.

• Applicable fields:

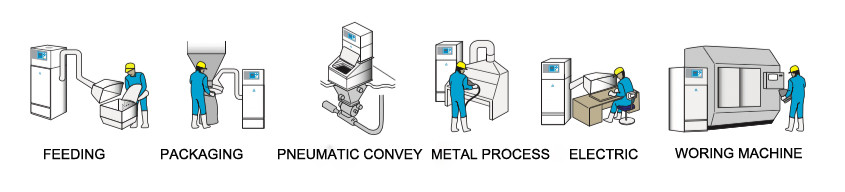

Application environment: temperature: -10°C -- +55.4 , relative air humidity no higher than 85%, with compressed air sourceAp. plication industry: chemistry industry, pharmaceutical industry, food processing, metal processing, compound material, electronics, building materials, electrostatic coating and other fine air particles.