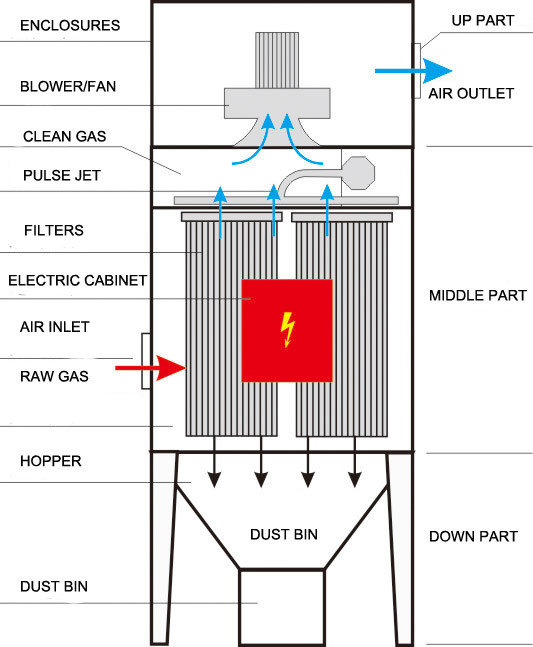

- Industrial Pulse Jet Dust Collector

- Laser Fume Extractor

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metal Dust Collection System

- Wet Scrubber

- Sinter Plated Filteration

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand blasting machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Pharmaceutical Dust Collection Application

The manufacture of pharmaceutical products such as medicine, vitamins, or minerals refers to a wide range of processes that can produce harmful dust. Some usual applications include: drying (spraying, rotating) , mixing, sieving, tablet pressing, packaging, coating, grinding / sizing, weighing, conveying and packaging of dry finished products.

Pharmaceutical dusts can pose unique challenges due to their potential chemical hazards on workers. Except worker protection, dust recovery and cross-contamination may also be critical considerations.

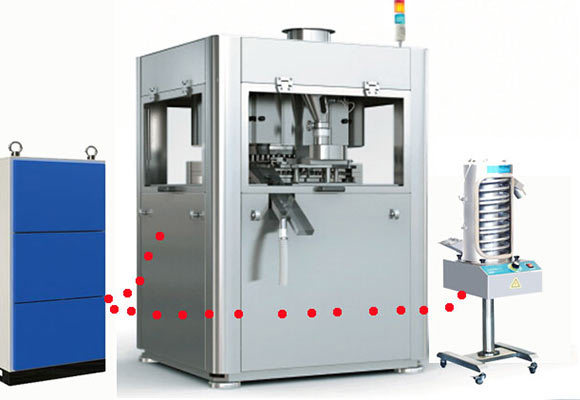

Tablet Press/Capsule Filling :Tablet Press Dust Extractor

|

For high speed rotary tablet press |

|

|

Features |

|

Air Volume | 1410-1704m³/h |

Fan Pressure | 3507-3203Pa |

|

Filter Material |

PE+PTFE Cartridge |

Motor Power | 3kw |

|

Filter Area |

27㎡ |

|

Dust Cleaning |

Air Back Flow |

Air Source | 0.4-0.6Mp |

|

Power |

~380 50Hz |

material | Q235/SUS304 |

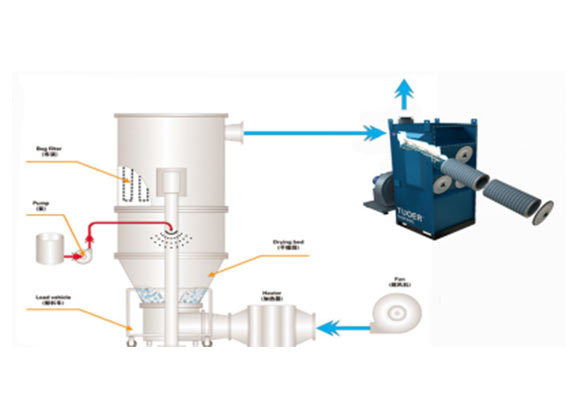

Fluidized Bed Drying/Coating/Grabulating

Secondary collection in granulator

| Advantages: 1:Body reinforce:sustain highpressure 2:Sus304 body: GMP standards 3:Cleaning:Pulse-jet air back flow 4:supply centrifigual fan 5:Pure surface filtration:PTFE Coating 6:multichoice:Donalson/NEPcartridge 7:manufactory OEM 8:High efficiency | |||

Model | Air Flow | Filter Area | Solenoid Valve No. | Sustain Pressure | Weight |

Tuoer15BF | 1500-3000 | 22.5 | 3 | 0~10000pa | ~265kg |

Tuoer30BF | 3000-4000 | 36 | 4 | 0~10000pa | ~300kg |

|

Tuoer4BF

|

4000-5000

|

48 | 4 |

0~10000pa

|

~340kg

|

|

Tuoer60BF

|

5000-7000

|

60 | 5 |

0~10000pa

|

~390kg

|

|

Tuoer80BF

|

7000-9000

|

75 | 5 |

0~10000pa

|

~430kg

|

Tuoer100BF | 10000 | 90 | 5 | 0~10000pa | ~480kg |

Love discounts? Subscribe to newsletter!

- Tel

- *Title

- *Content

- Upload

- Only supports .rar/.zip/.jpg/.png/.gif/.doc/.xls/.pdf, maximum 20MB.

- Industrial Pulse Jet Dust Collector

- Laser Fume Extractor

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metal Dust Collection System

- Wet Scrubber

- Sinter Plated Filteration

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand blasting machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System