Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

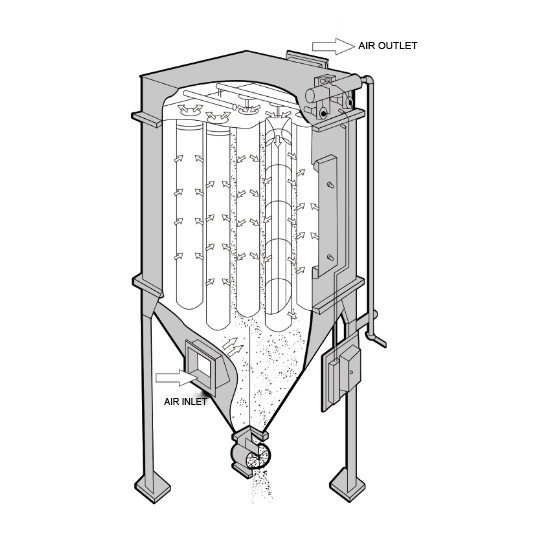

Bag House Dust Collector/Deduster/Extractor

Detail Information

Bag House Dust Collector/Deduster/Extractor Detail:

• Features:

DMC pulse bags filter makes the compressed air as the driving force for cleaning dust, the pulse injection organization releases the compressed air instantly and induces the secondary high-speed air into the filter bags to make the bags expand rapidly so as to shake off the dust and clean it. Series of the products. There are 24 bags. 36 bags. 48 bags, 60 bags. 72 bags. 84 bags. 96 bags.108bags.120bags.

• Peration principle:

Dust air enters cleaning trunk from the bottom of dust remover, Coarse dust particles fall into the dust cellar by its gravity: fine dust particles are attached on the surface of the filter bag by various effects. Dust grows thicker as time goes by. resistance for dust remover rises. which decreases air volume to be processed. Dust attached on the surface of the filter bag has to be removed to keep the dust remover in an effective working state and make pressure loss remain within a certain range. In cleaning process. controller is required to give out orders to each electromagnetic pulse valve. In this condition. filter bag conducts sudden contraction-expansion-contraction in an instant. Pressure loss of the dust remover and dust air quantity remain almost unchanged during dust removing process. which is also an advanced feature of pulsate bag dust remover.

• Applicable fields:

Chemistry industry. pharmaceutical industry. food processing. glass. quartz. ceramic clay. carbon materials. mechanical processing. building materials and abrasive materials.

SPECIFICATION PARAMETER

Mode | Air capacity(m³/h) | Resistance(Pa) | Filter area(m²) | Number(ps) | Efficiency(%) | Dimension(mm)(L×W×H) | Weight(Kg) |

DMC24-II | 2160-4300 | 1200-1500 | 20 | 24 | 99.99 | 1730×1060×3676 | 865 |

DMC36-II | 3250-6480 | 1200-1500 | 30 | 36 | 99.99 | 1730×1460×3676 | 1060 |

DMC48-II | 4320-8630 | 1200-1500 | 40 | 48 | 99.99 | 1730×1860×3676 | 1334 |

DMC60-II | 5400-10800 | 1200-1500 | 50 | 60 | 99.99 | 1730×2260×3676 | 1490 |

DMC72-II | 6450-12900 | 1200-1500 | 59 | 72 | 99.99 | 1730×2660×3676 | 1590 |

DMC84-II | 7500-15100 | 1200-1500 | 69 |

84

|

99.99

|

1730×3110×3676

|

1942

|

DMC96-II | 8650-17300 | 1200-1500 | 78 |

96

|

99.99

|

1730×3620×3676

|

2184

|

DMC120-II | 10800-20800 | 1200-1500 | 98 |

120

|

99.99

|

1730×4420×3676

|

2594

|

OPERATION PRINCIPLE

PRODUCT FAQ:

Q: Which situation is suitable for baghouse filter?

A: Bag type dust collector is the first generation filtration machine, and it suitable for dry material. In super high temperature raw gas (280 census degree), it has glassfiber bags, and also cheaper than others. And it is also suitable for big airflow central collection.

Q: The bag type dust collector's disadvantage?

A: The separation efficiency is low; the filter bag’s lifespan is short; the maintainance cost is high, the machine size is big, the compressed air consumption is high.

Q: The filter bag's size?

A: 130*3000mm, 130*5000mm, 130*8000mm, sometimes depends on the location size.

Q: Where is the Access door?

A: The Access door is on the dust collector’s top, and needs height to change the filter bag.

Contact Us

Wechat

+86 19550289881

Info@dustscrubber.com

+86 18768123711

Related Products

Please send your message to us

- Phone

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Phone

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web