How to Cooperate the Industrial Grinder with the Dust Collector

How to Cooperate the Industrial Grinder with the Dust Collector

small grinder dust collector

Generally used as small grinders such as small hand-grinding, surface grinding, tool grinding, etc.,

only fine grinding or dry grinding, it is recommended to use lower power vacuum cleaner mobile dust removal equipment, easy to move, simple dust collection method, economical, environmental protection, and low noise.

It also have a dust hood for your flexible usage, also suitable for home shop use.

This equipment have two stage filtration: cartridge filter and high efficiency filter bags.

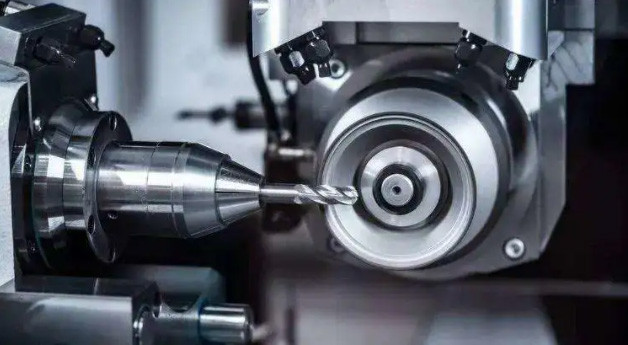

Big grinding machine

As a larger precision mill, or inner and outer cylindrical mill, in addition to the wet mill, consider using high-power large-air volume equipment as much as possible. First, from the perspective of dust collection and working efficiency, a single machine is equipped with a dust cleaner for point-to-point dust suction.

If the grinding fluid is combined with the workpiece during the fine grinding process, the wet dust removal equipment must be selected. In daily life, we all know that when the liquid and the solid are mixed, a layer of attached dust will be generated on the outer surface of the workpiece. Also because most cutting fluids are viscous fluids, in this case, it is generally recommended to use hydraulic equipment.

ACMAN dust removal equipment has remote control switch control system, frequency conversion control system, pulse spray cleaning system, etc. In general, we will use a fixed suction port for matching. In many factories, we can see that the grinder operator will wear a larger mask, but even after wearing the mask, it cannot solve the problem of pollutant discharge. Metal dust generally floats at a height of one meter on the ground, while lighter dust materials (such as plastic, wood powder, resin, etc.) will float at two meters or more. This is easy to cause some damage to the employees' lungs, and can not meet environmental standards.

If the above problem cannot be solved, the central dust collection system of the grinding machine can be customized for the grinding machine or a single large processing platform. Of course, there are two disadvantages in this system. The first is that the cost is very high, and the second is that it is inconvenient to move and demolish.

Rubber grinding process

Lot of rubber or tyre/tire material polishing or grinding should use wet scrubber to catch the flammable dust...