Home / All / Power Coating Machine/Powder Spraying System / XL Powder Coating Booth for Sale, Powder Coating Spray Booth, Powder Coating Recovery Booths Filter System

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

XL Powder Coating Booth for Sale, Powder Coating Spray Booth, Powder Coating Recovery Booths Filter System

Detail Information

XL Powder Coating Booth for Sale, Powder Coating Spray Booth, Powder Coating Recovery Booths Filter System

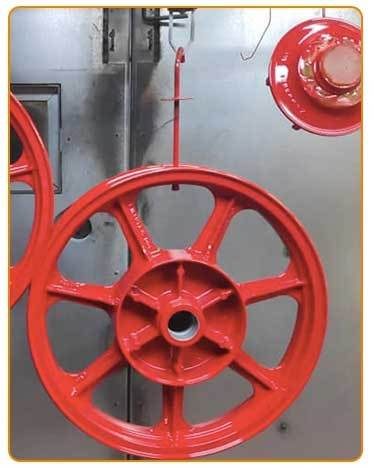

Powder Recycle Rate Reach 99%

This ACMAN POWE powder coating spray booth are consists of 8 systems:

1: Open Type Cabinet Body: Depending on different size of workpiece, ACMAN designed for 4 different size booth fitting for the clients requirements;

2: Filtration System: The filters is back installed on the booths which provide excellent filtration performance, the pleated offers 3 times of filtration area than traditional filters, whose powder recycle rate could reach 99%.

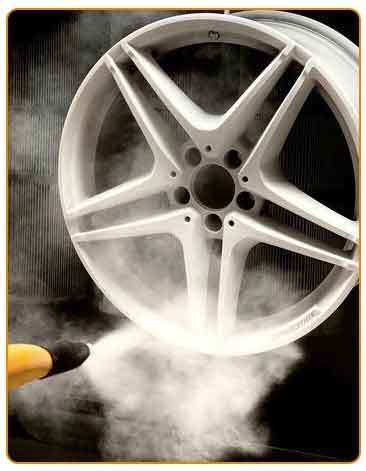

3: Filter Self-Cleaning System: POWE spray booth could clean the filter automatically. Thanks to the pulse jet cleaning system, the filters do not have risks of blocking;

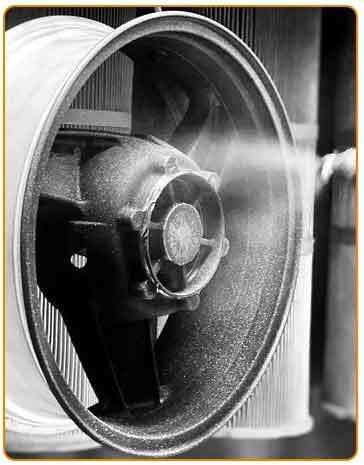

4: Centrifugal Fan system: The centrifugal fan provides big airflow and static pressure which making the system in a negative pressure atmosphere and could guarantee the powder not flying out;

5: Control System

Electric Control we use PLC, which could working smartly and data reveals directly.

It could control centrifugal fan running and stop, pulse

jet cleaning mode change and ect.

6: Powder Discharge System

The smart design of power discharge system consist of big volume dust drawer, wheels and a pneumatic sealing system.

pneumatic sealing system could separated the dust drawer directly.

7: Rail-mounted Hanger

The hanger could move on the top and easy for hanging the workpiece.

8: Lighting System

We design the lights which could lighting the cabinet inside and also a cover to protect the lights.

Details & Technical Data

|

Model

|

POWE-2315

|

|

Operation Size

|

Width2300 * Depth1500 * Height1500mm

|

|

Overall Size

|

Width2750 * Depth2070 * Height2180mm

|

Power Supply | AC 220V/380V (can be customized) |

Frequency | 50-60 HZ |

|

Power Consumption

|

4KW

|

Air Volume | 6677-13353m3/h |

Filters | Polyester |

Filter Count | 4pcs(325*900mm) |

Filter Cleaning System | pulse-jet system |

Machine Weight | 450kg |

Applications

Contact Us

Wechat

+86 19550289881

Info@dustscrubber.com

+86 18768123711

Related Products

Please send your message to us

- Mobile Phone

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Mobile Phone

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web