Home / All / PE Sinter-plated Filter and Equipment / Replacement of Herding Delta2 1500 φίλτρο πλάκας πυροσυσσωμάτωσης for COMP Dust Collector, Artikel Nr: S-3 Serien-Nr:D2-4

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

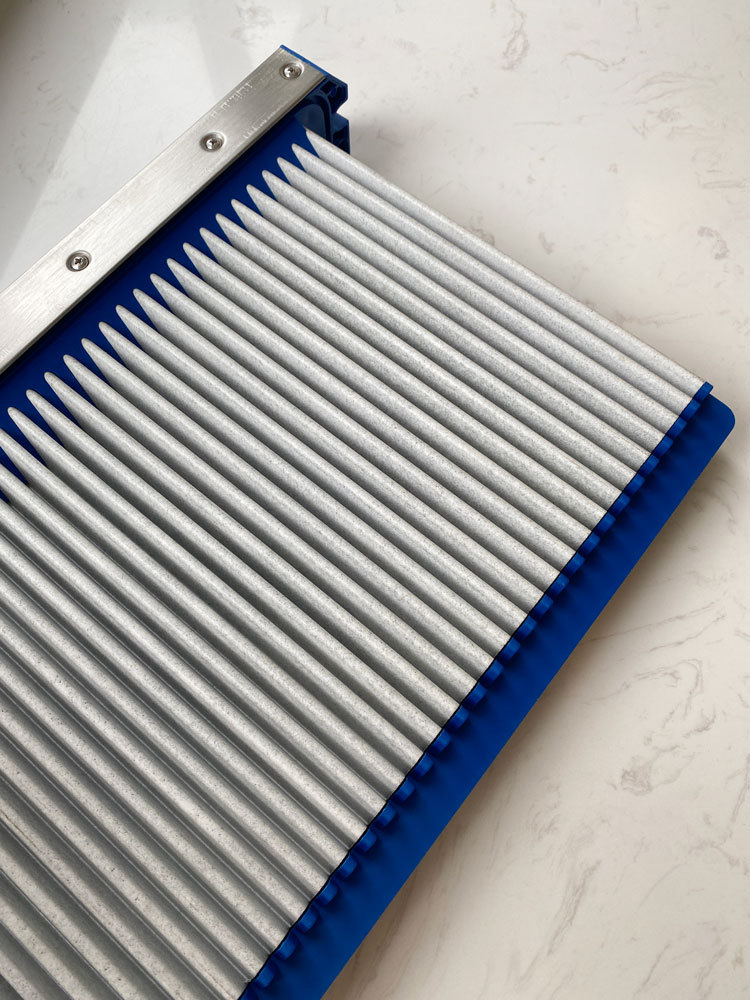

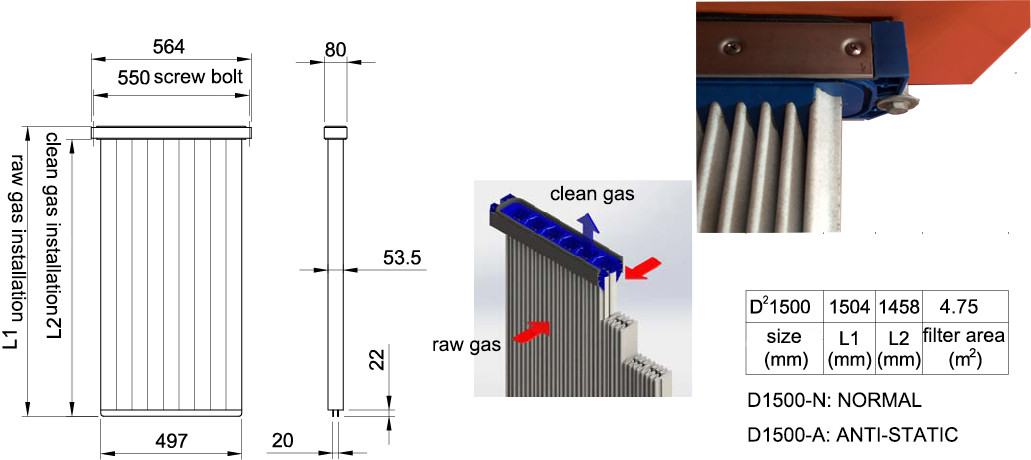

Replacement of Herding Delta2 1500 φίλτρο πλάκας πυροσυσσωμάτωσης for COMP Dust Collector, Artikel Nr: S-3 Serien-Nr:D2-4

Detail Information

Replacement of Herding Delta2 1500 φίλτρο πλάκας πυροσυσσωμάτωσης for COMP Dust Collector, Artikel Nr: S-3 Serien-Nr:D2-4

Advantage of Delta2 1500 φίλτρο πλάκας πυροσυσσωμάτωσης

Filter element lifetime of up to 15 years possible

Low maintenance costs due to long useful life of the filter elements

Constant pressure drop guarantees consistent air flow

High separation efficiency due to surface filtration

Clean gas emissions <1.0 mg/m3

Compact rigid body generates a robust filter design

Filter medium: capable to be washed, recycled and refurbished

Universal mounting from the raw- or clean gas side of the filter unit

Horizontal or vertical installation possible

Filter medium absolutely free of fibers, ideal for product recovery

Excellent use for highly abrasive dusts

Antistatic version of the filter elements available

FDA-conformity by using food-grade filter material

Low maintenance costs due to long useful life of the filter elements

Constant pressure drop guarantees consistent air flow

High separation efficiency due to surface filtration

Clean gas emissions <1.0 mg/m3

Compact rigid body generates a robust filter design

Filter medium: capable to be washed, recycled and refurbished

Universal mounting from the raw- or clean gas side of the filter unit

Horizontal or vertical installation possible

Filter medium absolutely free of fibers, ideal for product recovery

Excellent use for highly abrasive dusts

Antistatic version of the filter elements available

FDA-conformity by using food-grade filter material

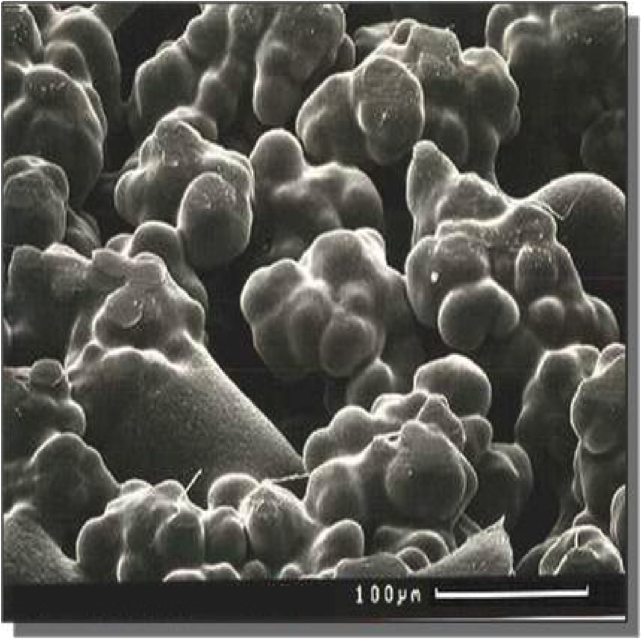

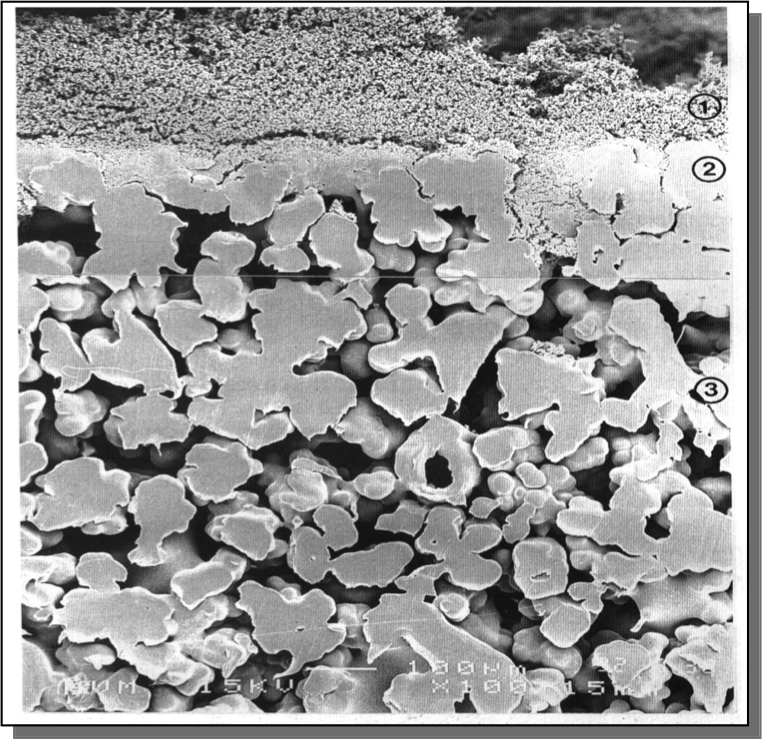

Basic Material of Sintered Filter

PE Base material

The body of the filter element is formed by a sintered polyethylene PE-matrix

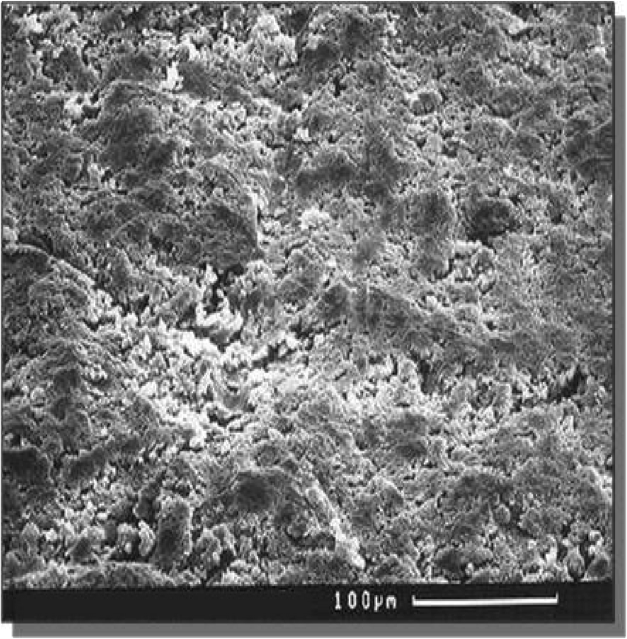

PTFE Coating:sintered plate filter's PTFE Coating

The filter surface is built by a micro-porous and hydrophobic PTFE-coating, which is firmly embedded into the pores of the PE-matrix.

1:dust:< 8 µm

3:PE base material:30 µm(4 mm thick)

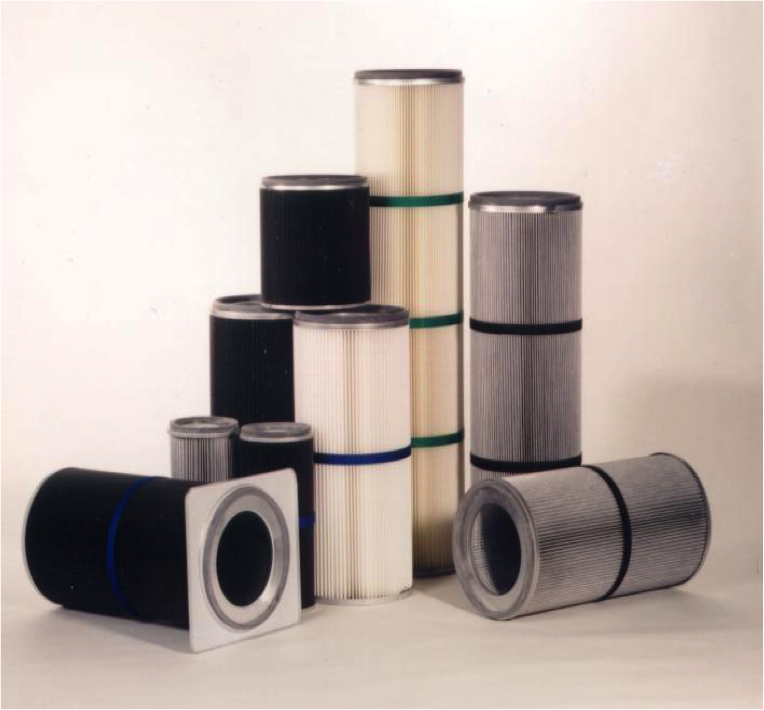

Filter bags VS Cartridge filters VS Sinter-plate filters

Filter bags

Advantage:

1:low price

2:sustain high temperature:280census degree

Disadvantage:

1:low efficiency;

2:high consumption of compressed air;

3:short lifespan

4:maintenance: hard to change the filters;

5:big size of the equipments.

Cartridge filters

Advantage:

1:high efficiency;

2:low price;

3:large filter area;

4:easy to install

Disadvantage:

1:not suitable for high abrasive dust;

2:hard to clean the folded material;

3:not suitable for high concentration dust;

4:less lifespan

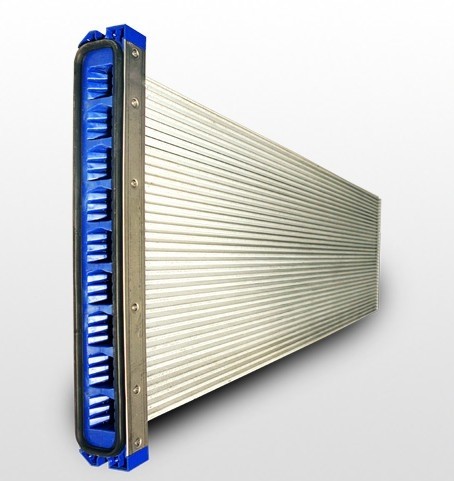

sinter plate filter

1:high efficiency;

2:lower emission;

3:long life time;

4:large filter area;

5:easy to mounting and change;

6:Acid and alkali resistant

Disadvantage:

1:temperature less than 80census degree.

sinter plated dust extractor use unique filters, not filter bags, cartridges, but UHMWPE sintering rigid filter with PTFE coating.

1. Can capture dust of 0.1μm particle size, extremely high industrial dust removal efficiency (H12);

2. The emission concentration is much less than 1mg/Nm3; the heating season dust collector switches to indoor discharge, which can save a lot of energy!

3. The coating is deeply embedded in the substrate, will not wear and tear, and maintain excellent filtration performance from beginning to end;

4.PE substrate + PTFE coating, pure surface filtration, stable resistance throughout the service life;

5. Rigid filter material, extremely wear-resistant, can achieve long life and reduce the consumption of compressed air; (life expectancy > 10 years)

6. PE and PTFE bring excellent chemical resistance;

7. Self-lubricating material, easy to clean ash;

8. Can be cleaned; 9. Absolutely free of silicon;

10. No fiber shedding, no risk of product contamination;

11. Compact shape, only 1/2~1/3 of the baghouse size, but still adapt to high inlet concentration;

12. Anti-static model optional(surface resistance ≤ 10E6, suitable for explosive dust);

2. The emission concentration is much less than 1mg/Nm3; the heating season dust collector switches to indoor discharge, which can save a lot of energy!

3. The coating is deeply embedded in the substrate, will not wear and tear, and maintain excellent filtration performance from beginning to end;

4.PE substrate + PTFE coating, pure surface filtration, stable resistance throughout the service life;

5. Rigid filter material, extremely wear-resistant, can achieve long life and reduce the consumption of compressed air; (life expectancy > 10 years)

6. PE and PTFE bring excellent chemical resistance;

7. Self-lubricating material, easy to clean ash;

8. Can be cleaned; 9. Absolutely free of silicon;

10. No fiber shedding, no risk of product contamination;

11. Compact shape, only 1/2~1/3 of the baghouse size, but still adapt to high inlet concentration;

12. Anti-static model optional(surface resistance ≤ 10E6, suitable for explosive dust);

Videos

Contact Email: Info@dustscrubber.com

Wechat

+86 19550289881

Info@dustscrubber.com

+86 18768123711

Related Products

Please send your message to us

- Mobile Phone

- *Title

- *Content

Love discounts? Subscribe to newsletter!

subscription

Send Inquiry

Please send your message to us

- Mobile Phone

- *Title

- *Content

Company

Categories

- Industrial Pulse Jet Dust Collector

- Cyclone Dust Collector

- Wet Scrubber

- Solder/Welding Fume Extractor

- Pharmaceutical Dust Collector

- Sandblasting Dust Collector

- Metalworking Dust Collection System

- Laser Fume Extractor

- PE Sinter-plated Filter and Equipment

- Dust Collection Auxiliary Equipment

- Central Vacuum Cleaning System/Unit

- Industrial Centrifugal Fan

- Sand Blasting Machine

- Bag In Bag Out Filter System

- Power Coating Machine/Powder Spraying System

Mobile Web